In any organization there are many departments that must work closely with other departments, for example in manufacturing Maintenance and Operations must work as partners, no matter what the relationship is called. One vital partnership is Maintenance and the Maintenance Stores – nothing is more important than getting the right parts to Maintenance people at the right time if you are to achieve a high level of maintenance effectiveness. While the Maintenance/Stores partnership is vitally important, it is difficult to develop and maintain because it requires a high level of discipline and determination by both parties. This article covers the responsibilities of both Maintenance and Stores to achieve success.

In my experience, many Maintenance Stores operations are very ineffective. The focus often seems to be on security by keeping the building locked, not allowing Maintenance people to physically look for parts and generally preventing losses. Sometimes the Stores goals are completely out of sync with Maintenance’s goals, for example Stores may focus on reducing inventory without understanding the consequences. I’ve even seen instances where Stores reports to Purchasing (Stores and Purchasing are very different functions) which in turn reports to a corporate “Procurement” organization. A structure that puts Stores so “organizationally remote” from its customer will always create service problems.

To develop a picture of an effective Maintenance Stores, its good to start with some principles, for example:

– Stores should have complete business processes, standards, systems, facilities and staff to control and protect maintenance materials (and perhaps tools – more on this later) from the time they enter the premises until they are used on a maintenance job. This should include stocked materials, “zero-stock” catalogue materials, direct purchases and some special parts that may be stored outside of the Stores building.

– Stores should make it as easy as possible for Maintenance people to find, select, obtain and, where necessary, return the materials they need while maintaining a high level of security at any time of the day (or night in a continuous operation).

– Materials should be stored and handled so that they will always be in a condition that will meet reliability goals when they leave Stores control.

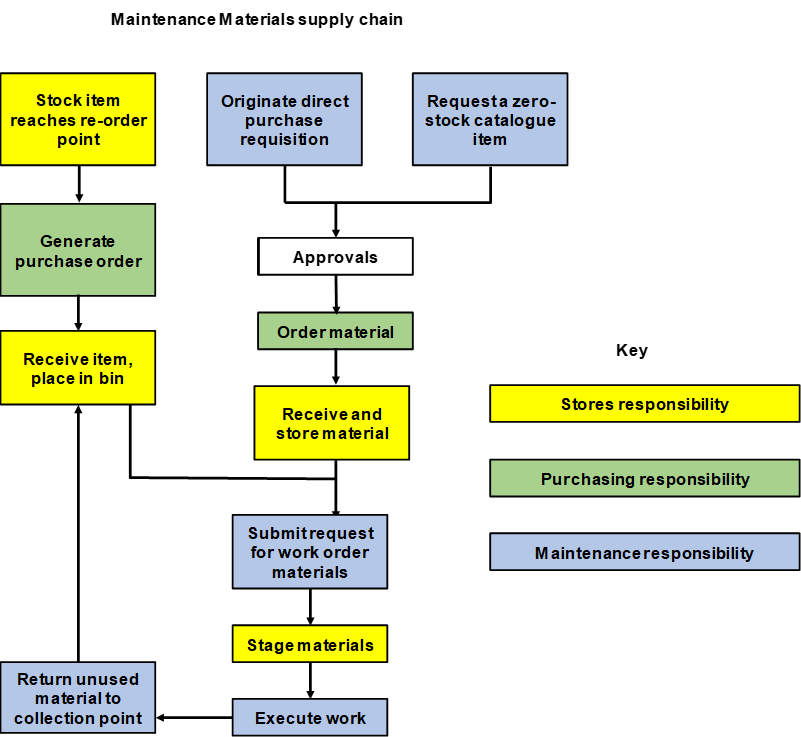

Following these principles, the “internal supply chain” for maintenance materials, with responsibilities, would look like this:

The implications of such a process are significant and require both Maintenance and Stores to work closely together for it to be completely successful. For example if Stores is to stage materials for maintenance work, as shown, Maintenance MUST advise Stores of all the material that is needed (a product of Planning) and tell Stores when it will be used (a product of Scheduling). Without good planning and scheduling, staging material will be very difficult and certainly wasteful. This requirement means that Stores effectiveness is extremely dependent on the discipline with which Operations and Maintenance can schedule maintenance work, and requires that scheduled work should be planned in detail.

Stores should support Maintenance by providing the following services:

– A robust and simple way for Maintenance people at all levels to find materials, supported by good naming standards, a comprehensive integrated “stock and non-stock” catalogue and willing help from Stores staff when needed, all supported by a highly functional computer system.

– A well-managed “free issue” system for small parts.

– A suitable physical facility adequately staffed to securely store, protect, control, retrieve, stage and deliver all stocked items and all direct purchased items, with robust racks and bins, each with a location number and showing the SKU number and the description of the parts contained in each bin.

– A secure location and facilities for staging “work order kits” for at least two weeks of non-shutdown maintenance work, if a weekly work scheduling process is in use.

– A suitable physical facility to securely store, protect, control, retrieve and deliver all materials for planned shutdowns.

– A simple process to accept returned items and ensure that they are fit for re-stocking.

– A process to manage repairable and serialized repairable spare parts.

– Record the location and movement of parts that are stored outside of the Stores building, with input from Maintenance and Operations people who are responsible for these parts.

– Sound basic inventory-management systems to immediately re-stock items that have reached their re-order point, replace items that have reached their shelf life and manage other basic inventory functions.

– Maintain an integrated catalogue of stocked and appropriate non-stock items, based on a naming standard that uses the same terminology as used by Maintenance people.

– Investigate stock-outs and advise Maintenance if they appear to be caused by equipment problems (e.g. increased usage) or by using maintenance stock for projects.

– Publish appropriate Key Performance Indicators that monitor Stores performance.

And because the Stores has the business processes to control the movement of materials both from and back to Stores, it makes good sense to include all objects that are used by Maintenance. This could include special tools and maintenance manuals, for example, but for these items it is especially important that the process is very simple, for example using a “tool tag” system and not a complicated computer system.

If the Maintenance “Statement of purpose” is “to provide our operating partners with a physical plant which, if operated correctly, will continue to meet all goals including production, quality, safety, and the environment at the lowest possible total cost over the long term” the Stores Statement of Purpose could be “to provide our Maintenance partners with all the materials they need at the right time and the right place and in a condition to support reliability goals, all at the lowest possible cost over the long term”.

And finally, to support Maintenance and Stores in managing materials and tools, managers must ensure that the operation has a very high level of security and that any instances of theft of company property are dealt with in a manner that will strongly discourage any further theft.

To return to the Articles index click here.

© Veleda Services Ltd

Don Armstrong, P.Eng, President

don.armstrong@veleda.ca

250-655-8267 Pacific Time

Canada