A well-managed work order backlog is essential for the efficient management of maintenance work. One of the common problems that make this difficult, and one which managers should manage, is a lack of discipline in closing work orders, so that a large part of the apparent backlog can get to be work that has already been done.

There should be a strict standard for closing work orders (or more correctly if using a maintenance computer system, changing their status to “physically complete”) and it is recommended that for non-shutdown work supervisors get into the habit of doing this important function at the end of each day. During a major shutdown, this may be assigned to someone who is tracking shutdown work progress, perhaps not the supervisor.

The other important discipline is to change the status of PM tasks to “cancelled” if they have not been completed before a new work order for the same task has been generated.

Closing work orders is a key part of the continuous improvement process, and it is at this step in each job that someone should have the responsibility to act on any input from the tradespeople who did the work. Tradespeople should answer three questions each time they perform corrective maintenance (repair) work. These questions include a simple form of root cause analysis and are:

– did the work need to be done?

– is there a better way to do it?

– is there anything that could be done to prevent this job from having to be done again, or at least to make it less frequent?

The answers to these questions, especially the last one, may lead to new work orders for further repairs or redesign, or to revisions to spare parts lists, PM procedures and frequencies or standard job plans.

The responsibility for following up on work order feedback should be defined in job descriptions and it is one function that logically can be a part of a Planner’s job, because the Planner sees all work as it is generated and can complete the loop by reviewing the information coming back from the work site.

Maintenance computer systems should make it extremely easy to close a work order. If the process is cumbersome it will inevitably be delayed – closing a work order is seldom seen as important as progressing other work, so whatever can be done to encourage it being done promptly will ensure consistency.

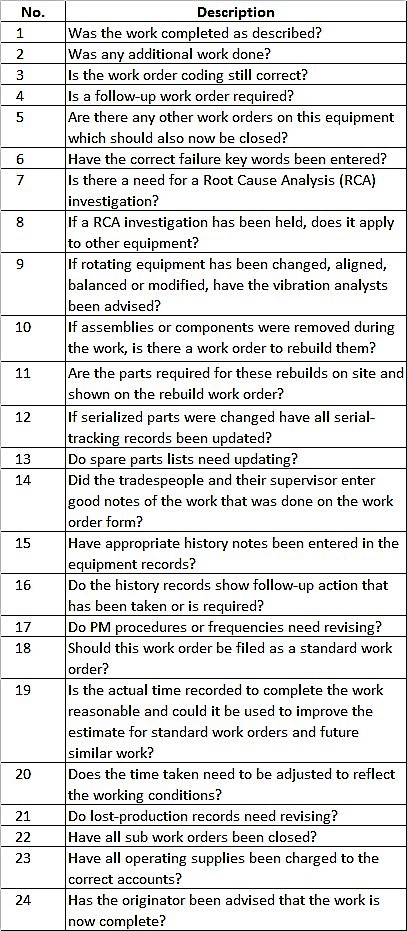

The table below contains a complete list of things that should be considered when a work order is closed.

.

Click here to return to the articles list

Management is getting people to do what you want them to do.

Leadership is getting people to want to do what you want them to do (dsa).

© Veleda Services

Don Armstrong, P. Eng (retired)

President, Veleda Services

dsarmstrong@shaw.ca

250-655-8267 Pacific Time