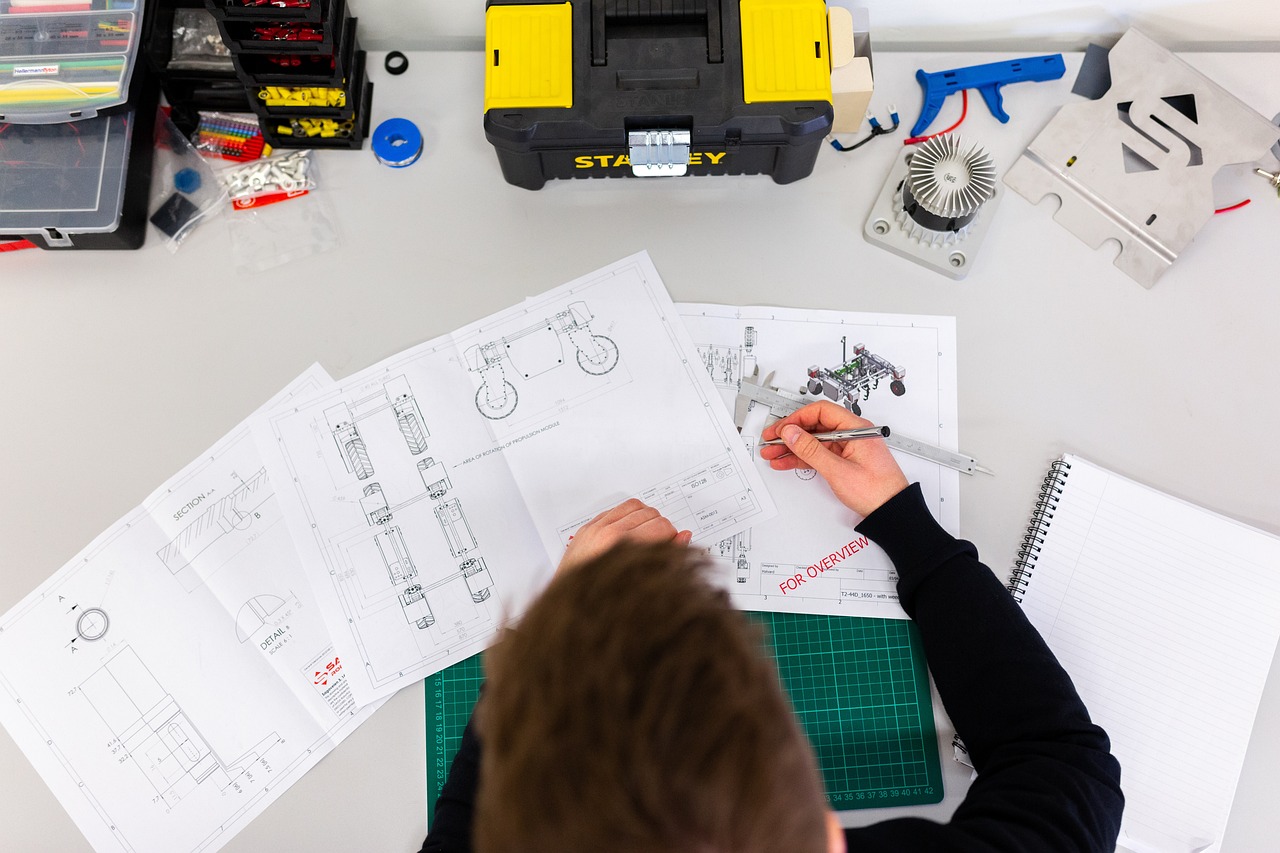

Some principles and a case study As an option to reduce plant costs, plant managers may consider contracting out maintenance work. This may have some merit, depending on many factors, including the nature of

In other articles on this site, we’ve discussed identifying the required outputs for a maintenance computer system as an early step toward database design. “Outputs” include all those documents or screens used by Maintenance

“Schedule compliance” or “Adherence to schedule” is a commonly-used Maintenance KPI (Key Performance Indicator) and is a measure of how much of the maintenance work scheduled for a maintenance crew, usually in one week,

This article will be easier to follow if you have watched Part 1 and Part 2 of the weekly scheduling videos. Following the guidelines in these videos you will be able to produce and maintain

Related articles Planning and scheduling – what are they? Scheduling – why is it so difficult? Scheduling – spreadsheets or critical-path software? Backlogs – their vital importance to Maintenance Setting work priorities Closing

Most organizations that use a weekly cycle for organizing maintenance work include a “scheduling meeting” as part of this process. Some are very effective and very short, many others are not but they could

In manufacturing, reliability is the product of Maintenance. But there are many factors that can limit the degree of reliability that Maintenance can deliver. One of the most significant is the inherent ability of

A very common complaint that I hear from Maintenance people in manufacturing operations where capital projects involving plant modifications have recently been completed, is that they are expected to maintain the new facilities but

One of the things that differentiates maintenance-management software from project-management and commercial inventory-management systems is that maintenance-management systems are used by many people, including operators, who may have had very little training in system

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia