Related articles:

Naming standards in the Stores

The “zero stock” catalogue and its power

Database management principles

This article covers the two main plant numbering systems that together form the framework on which all maintenance programmes are based and describes the value that can be created by integrating these identification systems.

These two systems are:

- Equipment Numbers, or more accurately, Equipment Location Numbers

- Stock-Keeping Unit (SKU) numbers or, preferably, Material Catalogue Numbers

A third, less critical but still important numbering system for Stores location (or “bin”) numbers, is also included.

Introduction

In a new plant, Equipment Location numbers (sometimes called “Asset Location” or “Functional Location” numbers) are usually assigned by the Engineering team responsible for the plant design because they are required during design and plant construction. The Material Catalogue numbers, however, are usually the responsibility of the plant’s start-up Stores management team, and the two databases are seldom integrated. This article looks at both systems in detail and explains how their integration can greatly simplify equipment, material and spare parts management.

1. Equipment location numbers

In any facility requiring maintenance, all assets from the plant level down to the smallest item of equipment should have one and only one identification number which is the basis for recording all important operating and cost information. The identification numbers for assets which are “stand alone”, such as manufacturing machinery, should be unique while identification numbers for infrastructure may be generic, as explained below.

Assets, except mobile equipment, should be identified and numbered by the space they occupy to maintain the integrity of the identification system as components move during their life span.

Equipment location numbers should be reflected in the General Ledger so that entering the equipment location number on work orders and other transactions will ensure that the correct accounts are charged at all levels.

Plant hierarchy

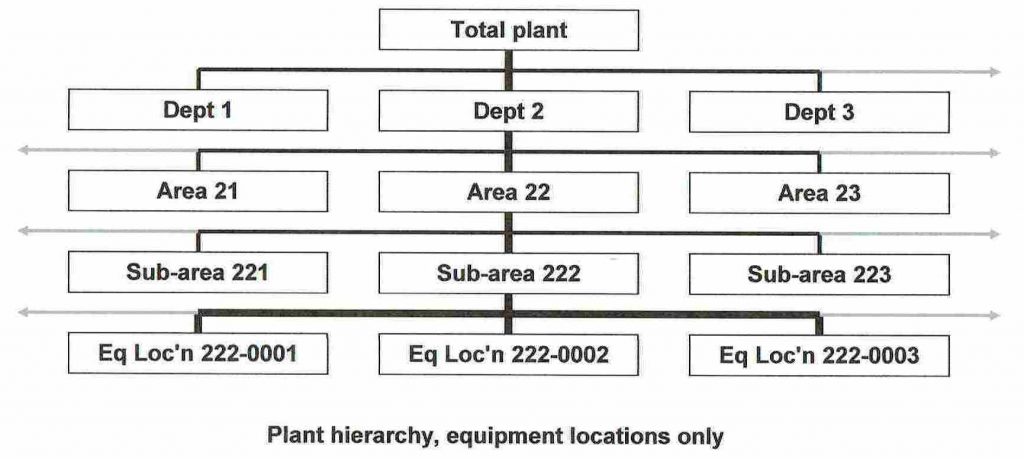

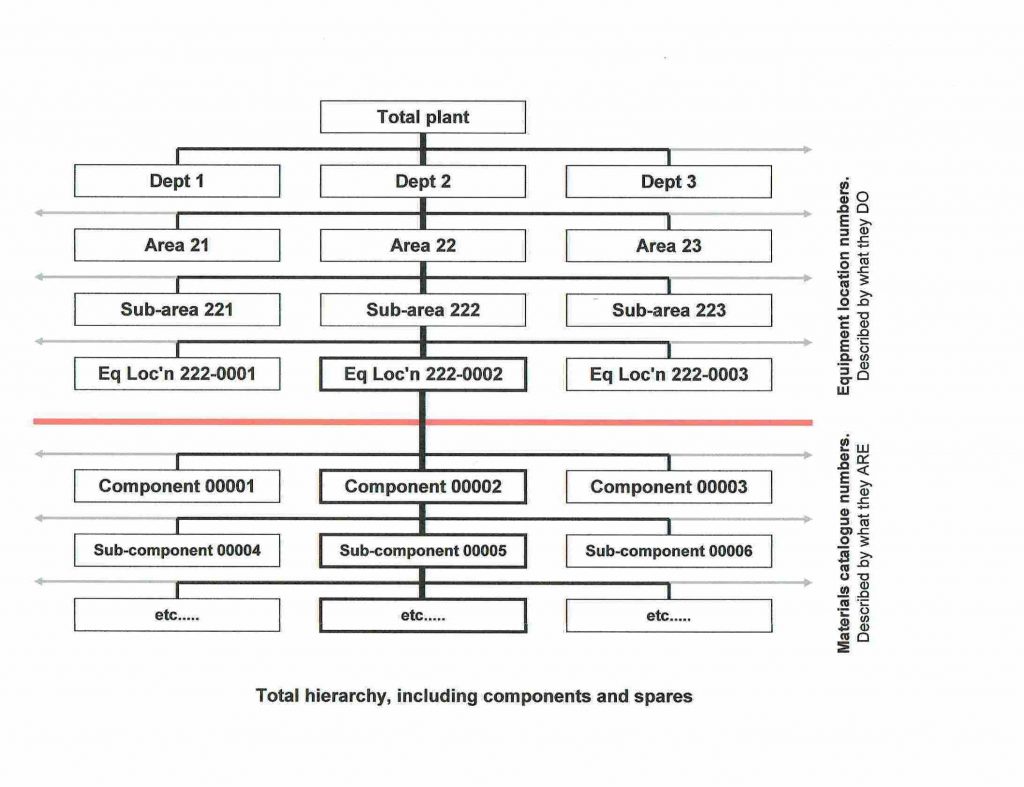

Equipment location numbers for both manufacturing equipment and infrastructure are usually grouped to form “Areas” which can, in turn, be grouped to form “Departments” or “Business units”. The hierarchy formed by such grouping should include the entire plant and the number of layers depends on the nature of the operation and its equipment. A typical structure and an example are shown below

The numbers applied to the boxes at the equipment level in this hierarchy have prefixes that identify the department and, perhaps, a “sub-department” and “area” if the plant is large and complex. These prefixes provide a quick check to confirm that the department is correct. Other than that, the equipment number may be just a sequential number, although some plants find that a character identifying some special equipment locations, such as control loops, is useful. Note that all equipment should be assigned location numbers with the same format, including mechanical, electrical, instruments and infrastructure.

The boundary between operating departments should normally be set at a process storage, and this is explained in more detail in the article “Organization Principles“.

Equipment location names

The names of equipment locations should describe the function that the equipment occupying the location performs, such as

– “Fan, Hot Air to No.3 Dryer”, or

– “No.6 Boiler Drum Level Control”

To ensure reliable searching for equipment location numbers, exactly the same principles that apply to the naming of parts in the Material Catalogue should also apply to the naming of equipment locations. These include:

– a clear distinction between “search” and “identification” terms

– the correct use of abbreviations

– a strict standard that an equipment location number is ALWAYS accompanied by a description in all documents, screens, labels, etc.

There is a very strong argument for two fields for equipment location descriptions, one unabbreviated and the other very much abbreviated (see “Maintenance database design from first principles”).

For more on these principles see “Naming Parts” and “Database Management“.

Types of equipment and their identification

The format of equipment location numbers will differ depending on the nature of the assets. Categories of equipment include:

manufacturing equipment including

a. simple rotating equipment and other discrete equipment

b. complex manufacturing equipment

c. piping and manual valves

d. buildings and other infrastructure

Manufacturing equipment

Unique manufacturing equipment location numbers should be assigned to all equipment locations which are part of the manufacturing process, such as rotating equipment (with any kind of prime mover), control loops, tanks, stacks, heat exchangers, etc.

Manufacturing equipment location identification is fundamental to good maintenance and operating management and the right equipment location number should appear on all the following documents:

– safety and isolation procedures

– all work orders and work requests

– operating control systems, such as distributed control system screens

– loss records and reliability reports

– engineering and other drawings and technical information and procedures

– preventive maintenance inspection and servicing procedures

– standard operating and maintenance procedures

– spare parts lists

– equipment history

– equipment maintenance cost reports

Because equipment location numbers are essential in these critical documents, once established they are very difficult to change and for this reason, the numbering system should be carefully designed. However, unless are you are at the preliminary stage of design for a new plant, you probably have an existing numbering system and nothing in this article suggests that you should change that. There are some suggestions here that you may be able to use to make your existing equipment location numbers more useful.

If you are in the process of selecting a maintenance computer system, be aware that some systems may require that equipment location numbers are changed to a different format. They may also limit the number of characters in equipment location names to the extent that the use of abbreviations is forced, which creates difficulties in searching. It is wise to avoid such systems if possible.

Older plants may have very valuable technical information for equipment locations in hard copy documents of which few people are aware. An example I observed was a very large bookshelf full of books of hand-drawn instrument loop diagrams where the material catalogue numbers were noted on each component. The cost of capturing this type of information and, if required, re-numbering equipment locations and materials catalogue items should be considered when installing maintenance software.

a. Simple manufacturing equipment

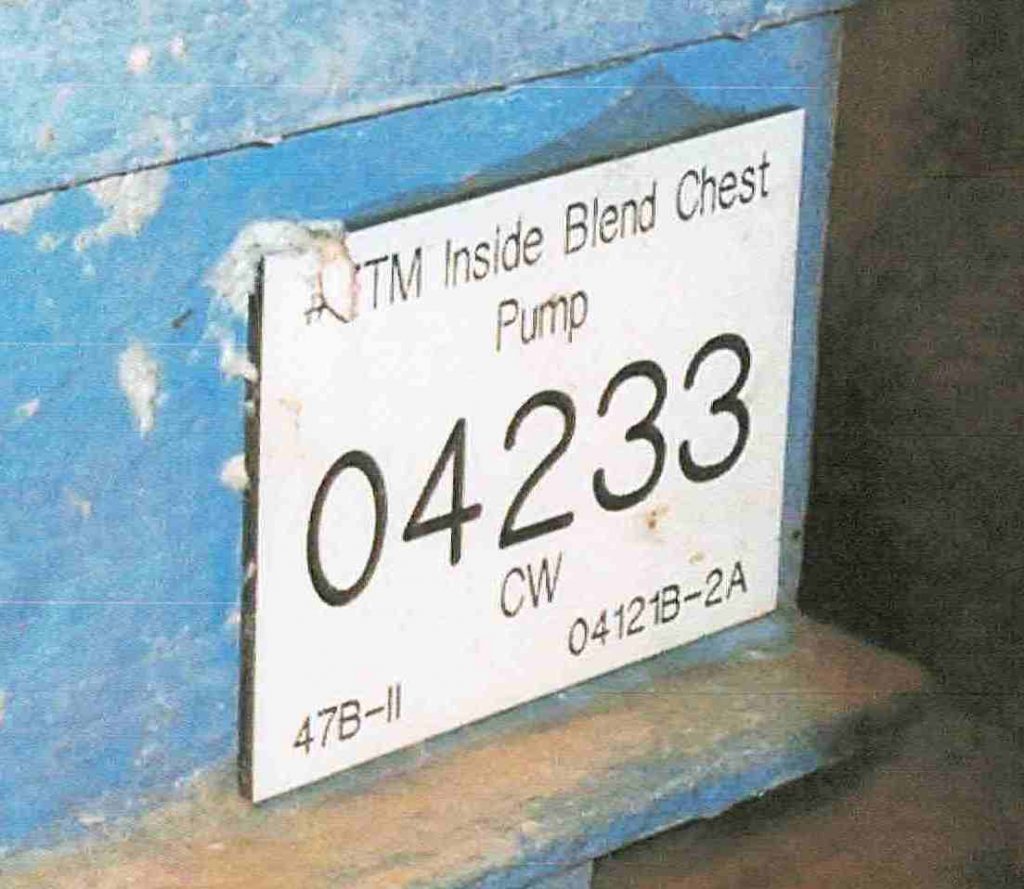

Equipment location numbers should be assigned to a location that is occupied by a number of components which together can perform some function, such as pumping liquid from one location to another, or filtering, shaping or drying a product in the manufacturing process, as in the picture below:

For this example, and other simple functional systems such as heat exchangers, control loops and tanks, a single equipment location number is all that is needed. In this example the equipment location number applies to all components that are needed to perform the required function. The function here is to pump liquid from one location to another and the components include the pump, coupling, motor, starter, base, local stop-start station and perhaps the suction and discharge valves (more on valves below).

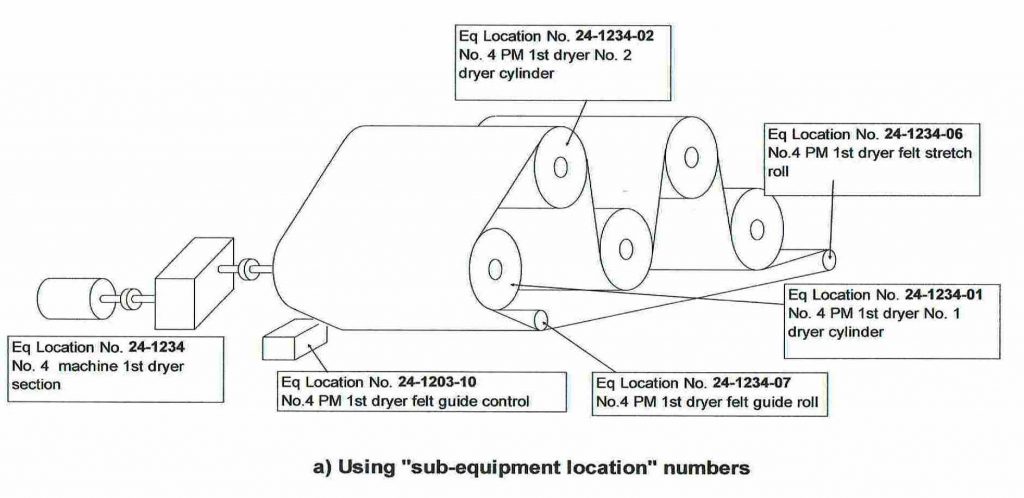

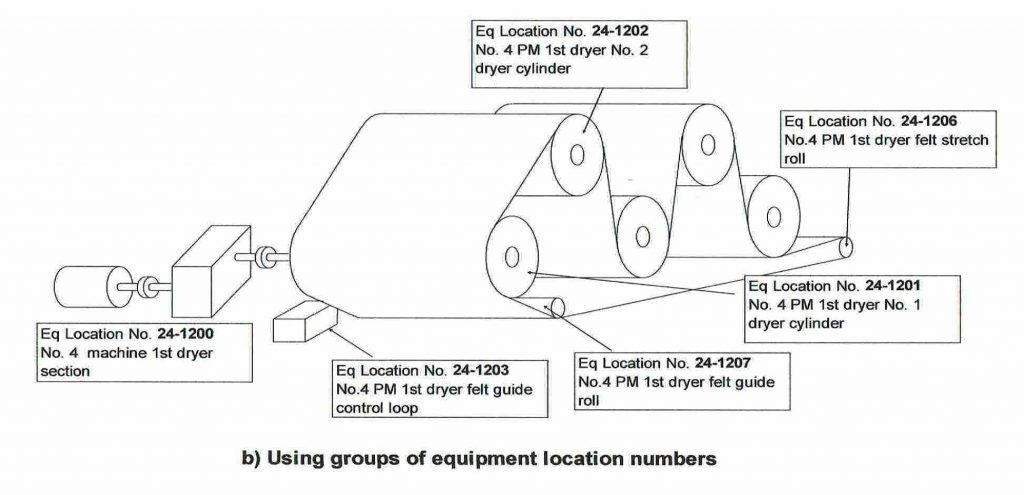

b. Complex manufacturing equipment

Some complex equipment, such as a paper machine (picture below) or steel rolling mill section, may have a single drive but many component locations that require individual management.

The numbering of the component locations requires careful planning, and two examples for a paper machine section are shown below. The first uses suffixes, or “sub” numbers and the second uses groups of location numbers. The first option is the more flexible, but the decision may depend on the functionality of the maintenance computer software. Note that all locations should use the same system – in this example the mechanical components and the control system both use the same number series and format.

Very large mobile equipment, such as mobile mining units, may be treated as a “department” and numbered accordingly, but most mobile equipment just needs an “equipment number” and their components should have material catalogue numbers, not equipment location numbers, and they should be included in the spare parts list for the equipment.

c. Piping, manual valves and electrical distribution

Piping and manual valves are special cases. Manual valves which are regularly used for controlling the process and especially valves which are used for isolating vessels and other equipment for safe entry should have equipment location numbers. Large isolating valves in water, air, effluent and other main systems are among the most difficult items in the plant to access for maintenance and should be clearly identified with equipment location numbers so that their servicing can be included in major shutdown plans without confusion (see “Equipment criticality ratings – are they of value?“).

Piping runs are assigned identifying numbers during design but they are difficult to identify physically because they may run for long distances. There are options, one of which is to standardize on treating piping as a component of the upstream or downstream connected equipment, but usually a more practical option is to treat them as infrastructure and to use a generic numbering system as described below.

Electrical distribution systems may follow the same logic as piping systems and should use an identification system that is consistent with that used for all other assets. Each and every electrical cable should be identified in detail using tags or sleeves on both ends.

-

Infrastructure

Buildings and outside areas which are not directly used for manufacturing are normally assigned generic numbers. A typical format is NN-XXXX where “NN” is the department number and “XXXX” is a standard suffix. An example of a generic numbering system is shown below.

Suffix Description Suffix Description

-7101 Mill air piping -8101 Buildings, general

-7102 Instrument air piping -8102 Structural steel

-7103 Mill service water piping -8103 Floors

-7104 300 psi water piping -8104 Walls

-7105 Potable water piping -8105 Doors

-7119 5% sulphuric acid piping -8106 Windows

-7120 50% caustic piping etc….

For non-manufacturing institutions, other numbering systems such as building and room numbers followed by generic suffixes may be more appropriate.

Of course, some items such as motorized doors and ventilation fans should have their own unique equipment location number.

Physical identification of functional locations

All equipment which has a unique (not generic) equipment number should have the name and number marked clearly on some part of the equipment location that is never likely to move, such as an equipment base. A good example of a label is shown below. Note that in this case the equipment location number does not have a department prefix, but the label does show other important information, such as the location of the motor starter.

Equipment numbers and names should also show on operators’ screens where a distributed control system is in use and process flow schematics are displayed.

A good standard for non-manufacturing institutions is to display the building and room number and perhaps a door number on all doors.

Searching for Equipment Location Numbers.

It is very important that the correct equipment location number is easy to find for both operators (who must include the equipment location number on all work requests) and maintenance people (to find parts lists and other technical information).

Many maintenance computer systems are designed with the expectation that users will “drill down” through the hierarchy to find the correct number. For untrained people this can be a complex and difficult process, and may be unreliable if the structure of the hierarchy is not consistent, a common problem.

A much easier way to find equipment numbers is with a “Google-like” search, where entering a search phrase such as “hot air fan” or “drum level control” will result in a short list of equipment locations from which the correct one can be easily identified. This search functionality is available in some good maintenance computer systems, or off-line search tools such as FindIt may be used.

Equipment number searching problems are very common, and in some plants we have seen maintenance backlogs where up to 50% of the work orders have an incorrect equipment location number.

“General” equipment location numbers

If the equipment location number is a mandatory field in all work requests and other commitments, as is should be, there is a need for a “pseudo” equipment number for some transactions. For example, for the purchase of shop supplies for the maintenance shop, an appropriate “equipment location number” for shop supplies may be required, against which a standing work order for the purchase of these supplies may be raised. This is one example of a legitimate and appropriate use of a standing work order. Of course, these special equipment location numbers may be included in the generic equipment location suffixes described above.

Equipment location numbers in multiple plants

Some large organizations require that the same equipment location numbering system is applied at all operations. This introduces a level of complexity and an administrative load that has little value and is not recommended. Individual, independent manufacturing facilities generally have little day-to-day interaction with their “sister” operations, especially at the equipment level, and if all plants have well-designed equipment location databases a common identification system is quite unnecessary.

2. Material Catalogue numbers

The other key numbering and identification system is the Materials Catalogue.

The origin of the Materials Catalogue is usually the establishment of Stock Keeping Units (SKU’s) for initial spare parts and supplies for a new plant and is normally the responsibility of the plant’s start-up Stores management team. As explained in the article “The ‘zero-stock; catalogue and its power“ initial SKU’s should be integrated with all other spare parts and supplies which are either stocked or not stocked to form the Materials Catalogue.

With a good, functional computer system the numbering system for the Materials Catalogue does not need to be any more complex than a sequential number, and even in a very large operation it is most unlikely that more than 6 digits will ever be needed.

The format of numbers for the Materials Catalogue should be very distinct from Equipment Location numbers. For this reason, it is a good practice to show leading zeroes in both numbers wherever they appear.

The naming of SKU’s and other Materials Catalogue items is covered in the article “Naming Parts“.

Spare Parts Lists

Spare parts lists are the documents that link the Equipment Location database and the Materials Catalogue database by showing which materials catalogue items are used in either each equipment location, or in other materials catalogue items which are assemblies.

Spare parts lists are, arguably, the most valuable source of information for Maintenance people and are covered in more detail in the article “Spare Parts lists – making them really work for you“.

Integration of Equipment Location Numbers and Materials Catalogue Numbers

Unfortunately, because the two numbering systems originate independently, they are seldom integrated. This lack of integration can result in some persistent problems which cause duplication of information and sometimes duplication of spare parts.

The most common logic error is to assign equipment location numbers to components, such as pumps or motors, within a location that contains a group of components which, together, perform a manufacturing function.

To illustrate the problems that this practice can cause, the following is an extract from the equipment register in a large paper mill:

Equip Loc’n No. Description

120627 PUMP, FAN TO NO.1 SCREENS

120627.310140 PUMP, INGERSOLL RAND 30X24 ALV

120627.333568 COUPLING, DB621-10M2

120627.430104 STARTER, 3.3KV FVNR LIMITAMP CR7160D

120627.430153 CONTROLS 3.3 LIMITAMP STARTER 120627

120627.540010 CONTROLS STOP LOCKOUT ONLY (CR2940NJ202A)

120627.50013 CONTROLS, EMERGENCY STOP ONLY

451894 MOTOR, 1500HP 746RPM SIEMENS FRAME 1LA16308FK00Z

This list is for the Equipment Location called “Fan pump to No.1 Screens” (Eq Loc’n 120627) and consists of 8 items in the equipment location database.

Lets look at just one item in this list, 120627.333568 – COUPLING, DB621-10M2. This is a standard coupling which is also used in six other locations in the mill and a spare is kept in stock (under Materials Catalogue No. 0062393). So in this example, this coupling has seven records which describe exactly the same item, 6 in the equipment location database and one in the materials catalogue.

In the above list, the only item which performs a manufacturing function is the first one, “PUMP, FAN TO #1 SCREENS”, and this equipment location contains the components listed, each of which should be recorded in the material catalogue and NOT in the equipment location register as explained below.

This kind of duplication of items in the equipment location database obviously results in a much larger equipment register and complicates the management and maintenance of the two key databases.

In the above list, note also that the motor number does not include the equipment location number. Inconsistent numbering and inconsistent use of fields among different mill departments, such as Electrical and Mechanical, are also a common problem.

NOTE – In some cases the justification for including a component in the equipment location database is that the component requires some modification from standard to be used in a particular location. For this example, the coupling may need to be bored and keyed to suit both the pump and motor shafts, and this machining information may have been included in a field in the equipment location database for this reason.

In all good maintenance computer systems, spare parts lists have a field for describing how (or where) any particular materials catalogue item is used on any item of equipment, and if this field is correctly used it completely eliminates the need for any component to be included in the equipment location database. This field is often not understood or correctly used and is covered in more detail in the article “Spare Parts Lists – making them really work for you“.

Integrated Asset Hierarchy

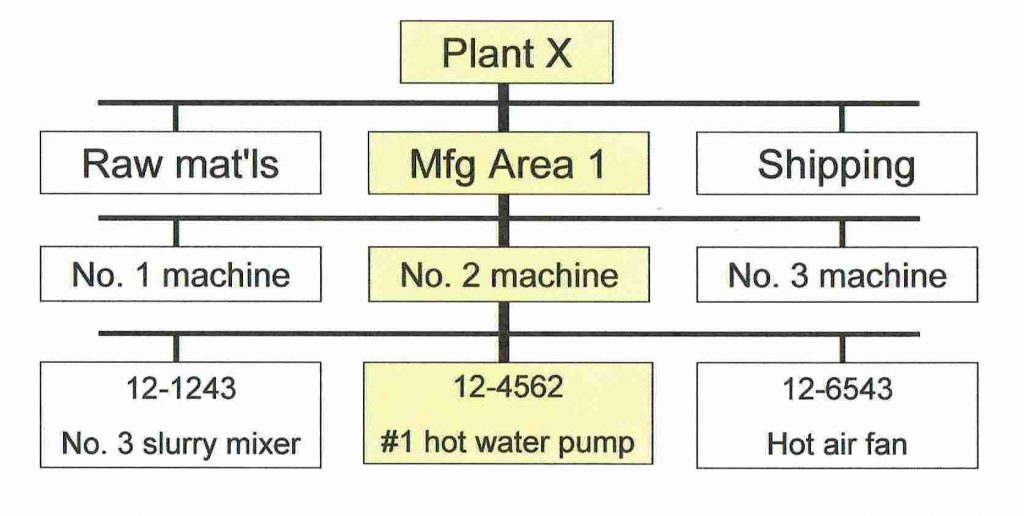

The integration of the Equipment Location database and the Materials Catalogue database results in a complete plant hierarchy as shown below.

This is the logical continuation of the equipment location hierarchy, and there is a distinct change at the horizontal red line.

Above the line, the boxes contain “equipment locations” with a number that contains the department identifier and a name that describe the process or manufacturing function that the equipment in the location performs.

Below the line, the boxes contain material catalogue items with a materials catalogue number and a name that describes what the item IS, not what it DOES.

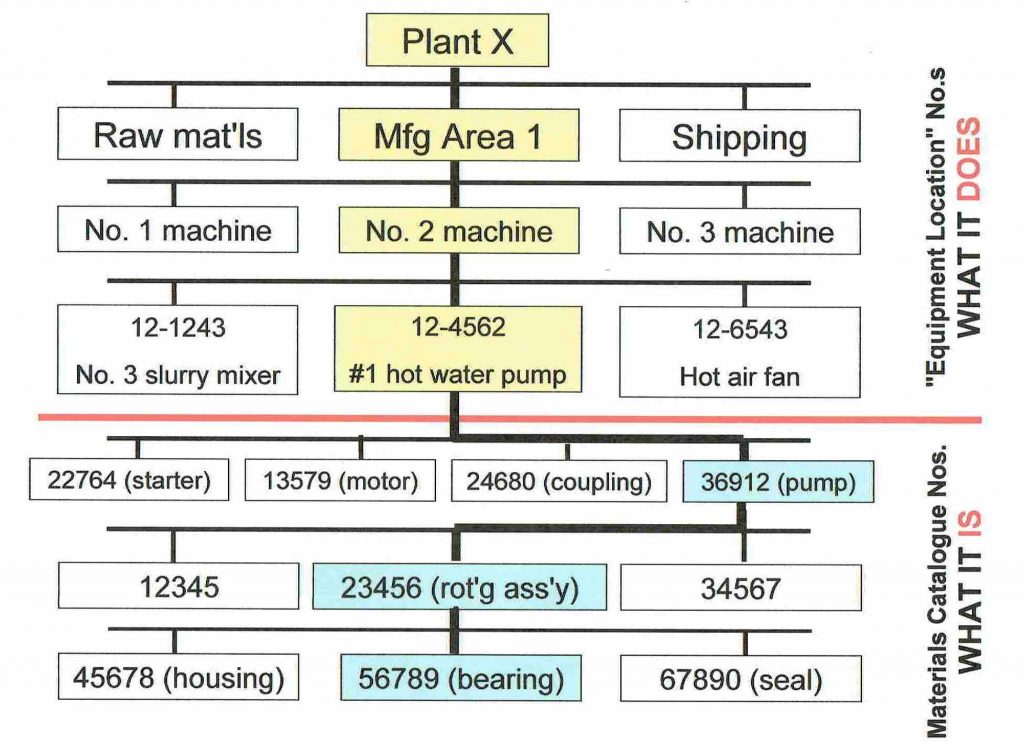

An example of an integrated hierarchy is shown below.

Spare parts lists should maintain the same structure as shown in the diagram. For example, the list of parts for the pump’s rotating assembly should be listed under the material catalogue number for the complete rotating assembly and NOT under the equipment location number for the pump/coupling/motor assembly.

For this reason, parts and components which are assemblies (such as the pump and the rotating assembly) and for which their component parts are either stocked or listed in the materials catalogue MUST be included in the materials catalogue themselves, whether they are stocked or not (see “The ‘zero-stock’ catalogue and its power“). If this standard is followed, then spare parts lists will update automatically if large components are replaced. For example, if the Goulds pump is replaced with a Worthington pump, then all that is needed is to make the change at the level just below the red line, and all the subordinate parts will automatically be updated for the new pump.

While changing equipment location numbers should be avoided, if you have an equipment location database that contains components, as in the fan pump example, consider removing these items and ensuring that they are correctly entered in the appropriate spare parts lists. This should not be a major project, and starting with the equipment locations which are most frequently maintained will ensure that the greatest value is quickly realized (see “Pareto Power in Maintenance“).

Stores location numbers

Some Storerooms are arranged by SKU (Materials Catalogue) number, which requires that these numbers are logically assigned to the appropriate spares and can not be random. This complicates the materials catalogue numbering process and creates difficulty if new parts are added.

The Materials Catalogue for stocked parts should include a field for the storage location. If this is done, then random numbering of SKU’s is possible.

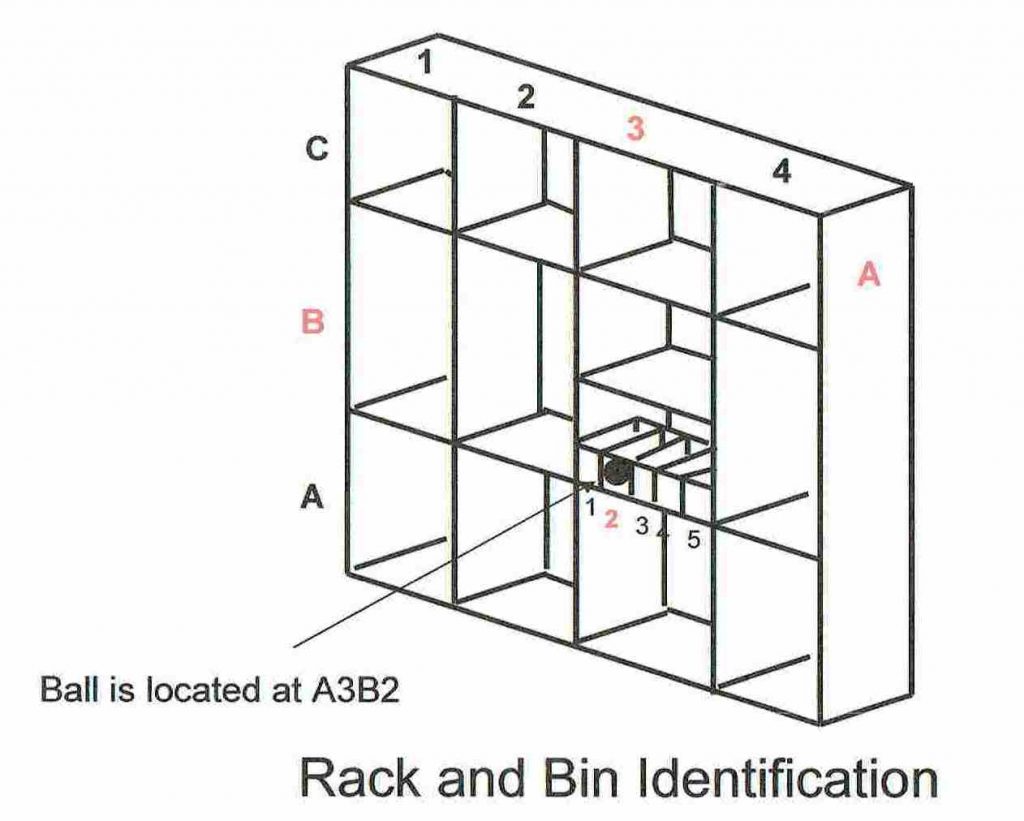

Storage locations, often call “bins”, should be identified using a logical system, and a map of the Stores layout should be posted at the counter to assist in locating parts. A typical rack and bin identification system is shown below:

All physical storage locations should be identified with both location number and the SKU number, whether they are located in the Stores or not. For example, large components which are stored in operating areas should be on racks or in bins with both numbers, whether stock is managed by Stores people or others. A typical “field” storage unit is shown below. The number on each rack is the equipment location number where each roll is used. Each should also have an SKU number and, ideally, a bin number.

To return to the “Articles” index click here

© Veleda Services Ltd

Don Armstrong, President