Related articles: Naming standards in the Stores Spare Parts lists The “zero stock” catalogue and its power Database management principles Organization principles This article covers the two main plant numbering systems that together form

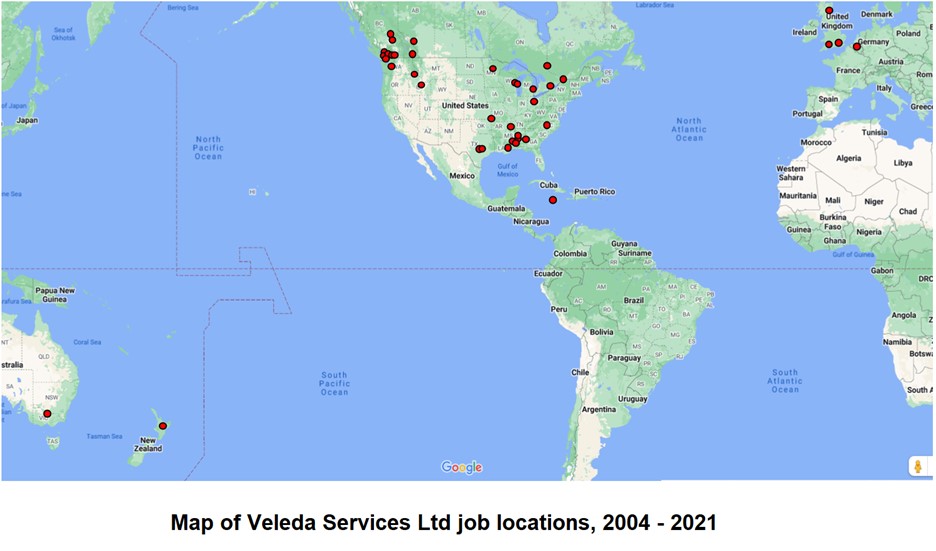

Congratulations! I think – the job you have is full of challenges and will keep you busy and probably awake at least some nights. I’ve been the maintenance manager in four large pulp and

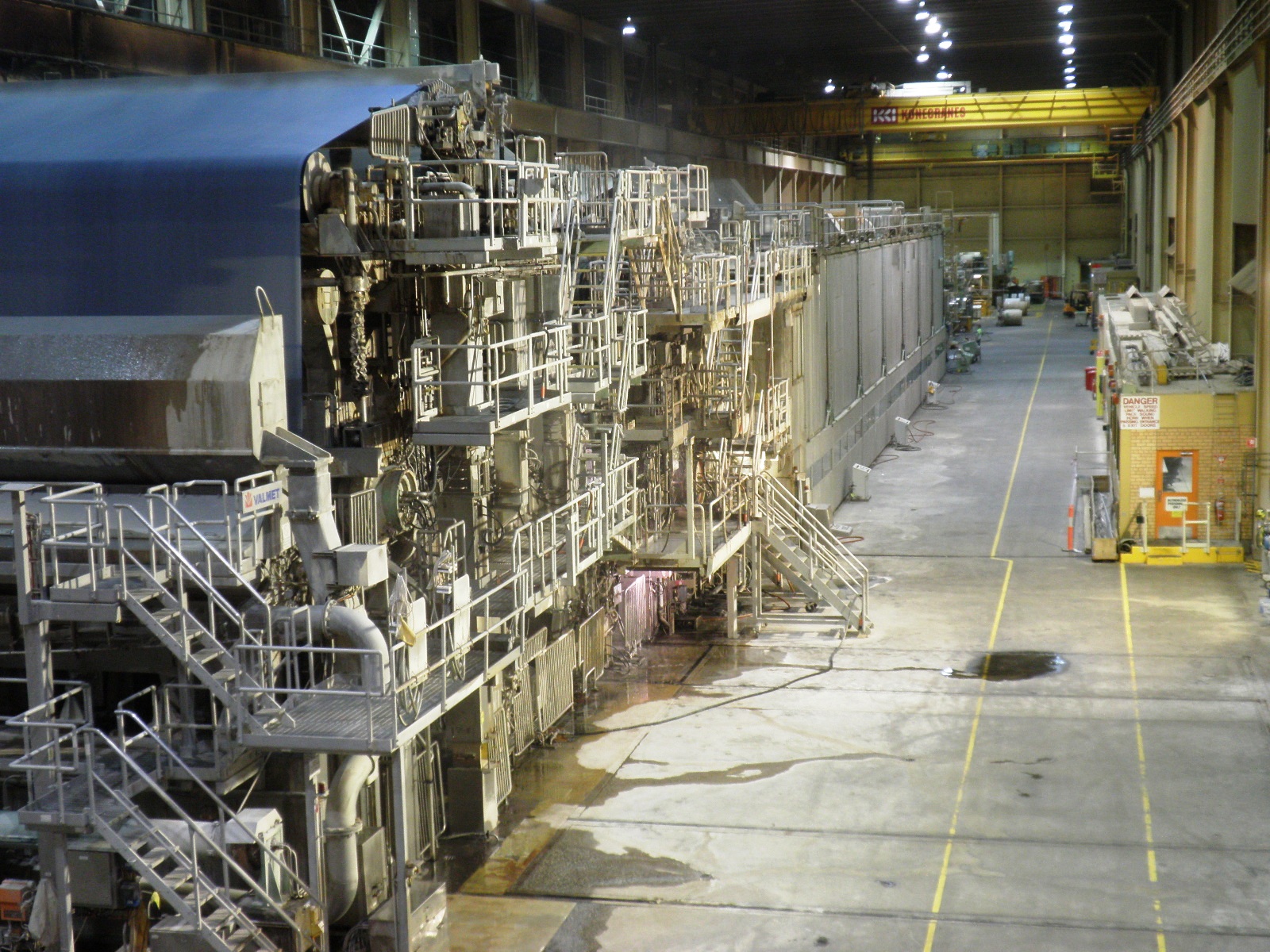

This map shows the locations of the projects completed by Veleda Services Ltd

Several years ago, when I was trying to get approval to hire an additional machinist, my boss, who was a very smart mill manager, said “Don, I do believe that if you had twice

See also – “Root cause, a discussion” There are six key steps in addressing the root cause of problems 1 – Describe all the symptoms of the problem in detail 2 – Identify

A fundamental component of your reliability programme is a well-structured equipment inspection process. If good design standards (such as the use of mesh safety screens for belts and couplings) have been followed during the

This article contains a list of a few of the things that should be considered when implementing a maintenance computer system, with some good and bad examples. Many of these tips can also be

One of the most important relationships that exists in any manufacturing operation, and in many institutions, is the Operations (or building manager) /Maintenance partnership. As has been covered in some of our other articles,

All Maintenance business processes should be under constant review to ensure that they are promoting the activities that will give the best reliability and other desirable results. These processes include the work order system,

As a maintenance mechanic it almost goes without saying that an essential step in most detailed work plans is to check your work before you hand the equipment back to the operator. Sometimes that’s