In an industrial setting, reliability is the “product” of Maintenance, so its very important that it be measured. Maintenance is expensive, and you should know what it is buying you.

There are many ways to measure reliability, and the measurements should provide information that is useful for reliability management. The measurement process should not take too much time or effort.

The best way to make reliability measurements useful is to record losses at the “equipment location” level, which is normally the level at which individual items of manufacturing or processing equipment are identified and numbered.

“Losses” are the units of production which were not manufactured (or were not of saleable quality) because of planned or unplanned downtime or slowdowns of equipment. Unplanned losses may have a number of causes, including insufficient incoming inventory, too much outgoing inventory, raw material quality, equipment breakdowns or slowdowns, lack of trained operators, etc. Planned losses result from shutdowns or slowdowns to inspect, clean, maintain, service or modify equipment.

The best way to record losses is to:

– establish the maximum production rate for each major manufacturing unit (usually a manufacturing operation which has some incoming and outgoing storage for process inventory) for each product or product grade.

– establish a target production for each manufacturing unit for each product (e.g. 90% of maximum production) for each shift worked.

– account for all losses below this target, using a simple recording system, as described below.

– review all losses for each shift and ensure that they have been recorded in a way that will allow the information gathered to be used to identify opportunities for improvement. There should be a position, such as a reliability or process engineer, with the responsibility for these daily reviews.

– regularly analyze loss records and use the information to develop and maintain a programme of continuous improvement, always focusing on the highest value opportunities.

Losses should be recorded as soon as they occur, usually by the department operator because that’s the one position that is always there and knows about each event.

To see an example of a loss-recording form, click here.

A simple paper form could be used, but an electronic log is preferred so that the information does not have to be re-entered for analysis. Some maintenance computer systems have the functionality to record losses, but most do not. A suitable log can be designed and built for your operation, and a good source is North Cove Technical Services (click here for their web site).

The information to be recorded by the operator for each event as soon as it occurs should include:

– the name of the manufacturing unit

– the date and time the event started

– the date and time the event ended

– the number of production units lost

– the cause of the loss (if known)

– the equipment number and description if the loss is caused by an equipment problem

– any other information which may be of use in future analysis

The daily reviews by the operating specialist should review the information, confirm the cause and assign responsibility, e.g. Operations, Mechanical, Electrical, etc. NOTE. The department to which the loss is assigned should be the department which is in the best position to ensure it does not happen again. It is NOT the department which is “to blame” (see “Allocating and analyzing downtime“).

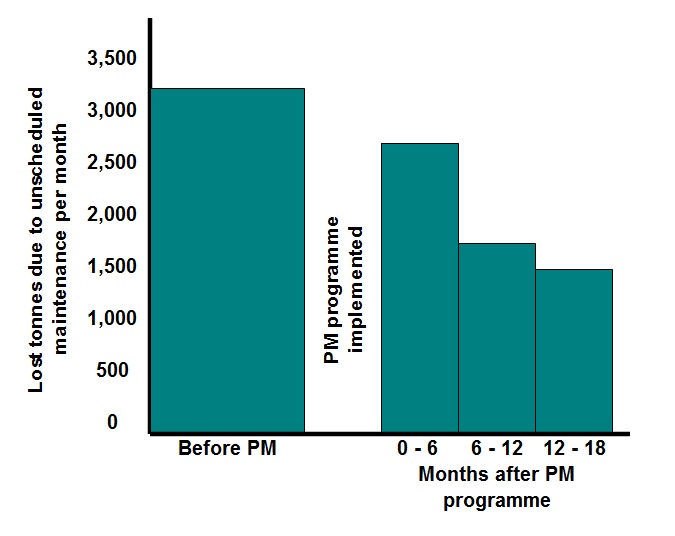

The graph below shows one result of using such a loss recording system. After analyzing 2 years of production loss records, it was found that 87 of 12,000 items of equipment contributed 80% of all unscheduled downtime. A preventive maintenance programme focusing on these 87 items and similar equipment resulted in the loss reduction shown in the graph.

There are other ways of measuring reliability, such as automated Overall Equipment Effectiveness (OEE) instrumentation, and these may well be justified in certain circumstances.

Reliability is the most important and useful KPI for Maintenance and should be reported regularly, with the ability to filter for each operating department and maintenance discipline. The results form the basis for a programme of continuous improvement.

Click here to return to the articles list

Management is getting people to do what you want them to do.

Leadership is getting people to want to do what you want them to do (dsa).

© Veleda Services

Don Armstrong, P. Eng (retired)

President, Veleda Services

dsarmstrong@shaw.ca

250-655-8267 Pacific Time