It is not uncommon for “criticality” ratings to be assigned to equipment, a practice which has some merit but the overall value may be questionable, as explained in this article.

“Equipment criticality” is usually defined as “the consequence of failure of the equipment” and may be given a rating. A typical criticality rating for consequences that impact production in a multi-line process manufacturing operation is shown below. Where such a scale is used, there will probably be similar ratings for consequences related to safety, the environment and for the impact on employee, community or customer relations.

*or the equivalent lost production to the defined shut down, through a slowdown or unsaleable quality.

The criticality rating may be recorded against each item of equipment in the equipment register and used by the various maintenance business processes to provide special functions, e.g. to automate expediting for repairs to spare parts for critical equipment, or to select a distinctive label for repair tags. If used for such purposes, then the rating has value.

Using criticality for setting maintenance priorities

The problem with criticality ratings is that they sometimes change and they do not take in to account the probability of failure.

For example, a particular pump may be so important to production that it has an installed spare. Because of this spare, a failure would shut a production line down for only one hour to switch pumps, so would have a criticality rating of 6. However, if the pump, or its spare, is removed for repair, then the failure of the remaining pump would shut down the line for 10 hours while it is repaired, so its criticality rating should change from 6 to 4. Keeping criticality ratings up to date for this kind of change is an administrative task that is unlikely to be managed with discipline in most operations.

Criticality ratings will also change when spare parts are being replenished (i.e. are temporarily out of stock), and may change when different products are being produced.

If an item of equipment has a high criticality rating it does not necessarily mean that any failure it experiences must have a high priority when scheduling maintenance work, for two reasons.

Firstly, just because an item of equipment has a high criticality rating based on the impact it will have on production, it does not mean that the failure of all of its components should have the same rating. For example, a large piece of mobile equipment may be very critical to the operation, however, while the failure of an engine or of a wiper blade may both shut down the equipment, the time out of service will obviously differ. Similarly for a pump handling a dangerous chemical the safety consequences of a mechanical seal failure may be much greater than a motor failure. For this reason, some have recommended that criticality ratings be assigned at the component level, or even the failure mode level, however this obviously introduces a much great level of administration.

Secondly, the probability of a production interruption must be considered. Very critical equipment will usually have some modes of failure that have a very long failure development period (e.g. wear on boiler superheater tubes) so their repairs may be planned for months or years in advance while maintenance on much less critical equipment continues.

Maintenance work on production equipment should be prioritized in terms of risk, usually the risk of a breakdown occurring prior to the next scheduled opportunity to do the necessary repairs. This risk is calculated as the consequence of failure (or “criticality”) multiplied by the probability of failure in that period.

While the consequences of any mode of failure of any component on any equipment can usually be fairly accurately estimated, the probability of failure is much less easily determined. Predictive maintenance techniques may help to quantify the probability but usually it is experienced Maintenance and Operating people who are in the best position to make that assessment.

Experienced Maintenance and Operating people usually have a very good idea of the criticality of equipment, without needing a rating system. In fact, they are the people who, most probably, will provide the criticality ratings for recording. A good Operations/ Maintenance relationship with disciplined backlog management supported by a practical preventive maintenance programme is, in my opinion, preferable to a formal criticality rating system. The cost of implementation and ongoing maintenance of criticality ratings is not insignificant, and incorrect ratings, if used blindly for setting work priorities, will undoubtedly result in some unnecessary losses or costs.

For more see “Setting Work Priorities”

Designing for criticality

Most manufacturing plants have a set of component standards to assist in the purchase of parts and to minimize the number of spare parts in inventory. These components are usually selected to provide the required reliability at the lowest cost. For example, for 150 psi steam a certain manufacturer and type of valve may be specified for all isolating points.

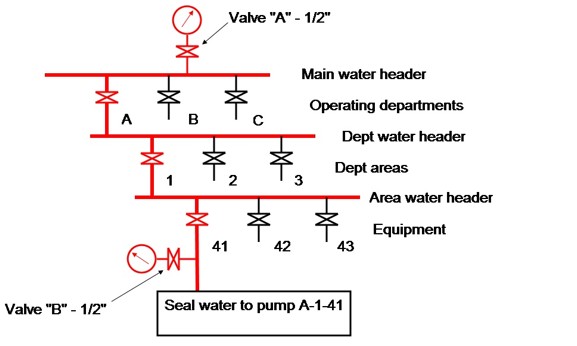

However, an experienced designer will also take the criticality of service in to account when selecting components. The schematic below is of the water distribution system for a large paper mill with three independent operating lines.

Valves “A” and “B” both see the same conditions (cold water at about the same pressure and temperature) so the same valve would do an adequate job of isolating each pressure gauge. Should valve “B” fail a very local shutdown, or perhaps no shutdown at all, would be required to replace it. However, if valve “A” were to fail, it could not be replaced without a total plant shutdown. If criticalities are considered during design, valve “B” should be a good industrial-quality valve while valve “A” should be the best that money can buy.

Similarly, the main header isolating valves at “A”, “B” and “C” each require a major plant shutdown for maintenance access and should also be of a very high quality. They are also likely to be closed very infrequently and the valve selection should take this aspect of their “operating context” in to account.

Main isolating devices in electrical, water, air, effluent and other essential plant services are often the only equipment or components in the plant which will have a criticality rating of “1” (using the rating table at the top of this article)

Equipment criticalities are essential to consider during design, and are always considered by experienced Operating and Maintenance people when setting work priorities. However, a “criticality rating” in the equipment records may be of little help to these people. Where they may have value is to provide some guidance for staff who support the operation but are not closely involved in day-to-day operation and maintenance, such as Purchasing and the Storeroom.

Click here to return to the articles list

Management is getting people to do what you want them to do.

Leadership is getting people to want to do what you want them to do (dsa).

© Veleda Services

Don Armstrong, P. Eng (retired)

President, Veleda Services

dsarmstrong@shaw.ca

250-655-8267 Pacific Time